info@stonefabricatorsolutions.com

M1x

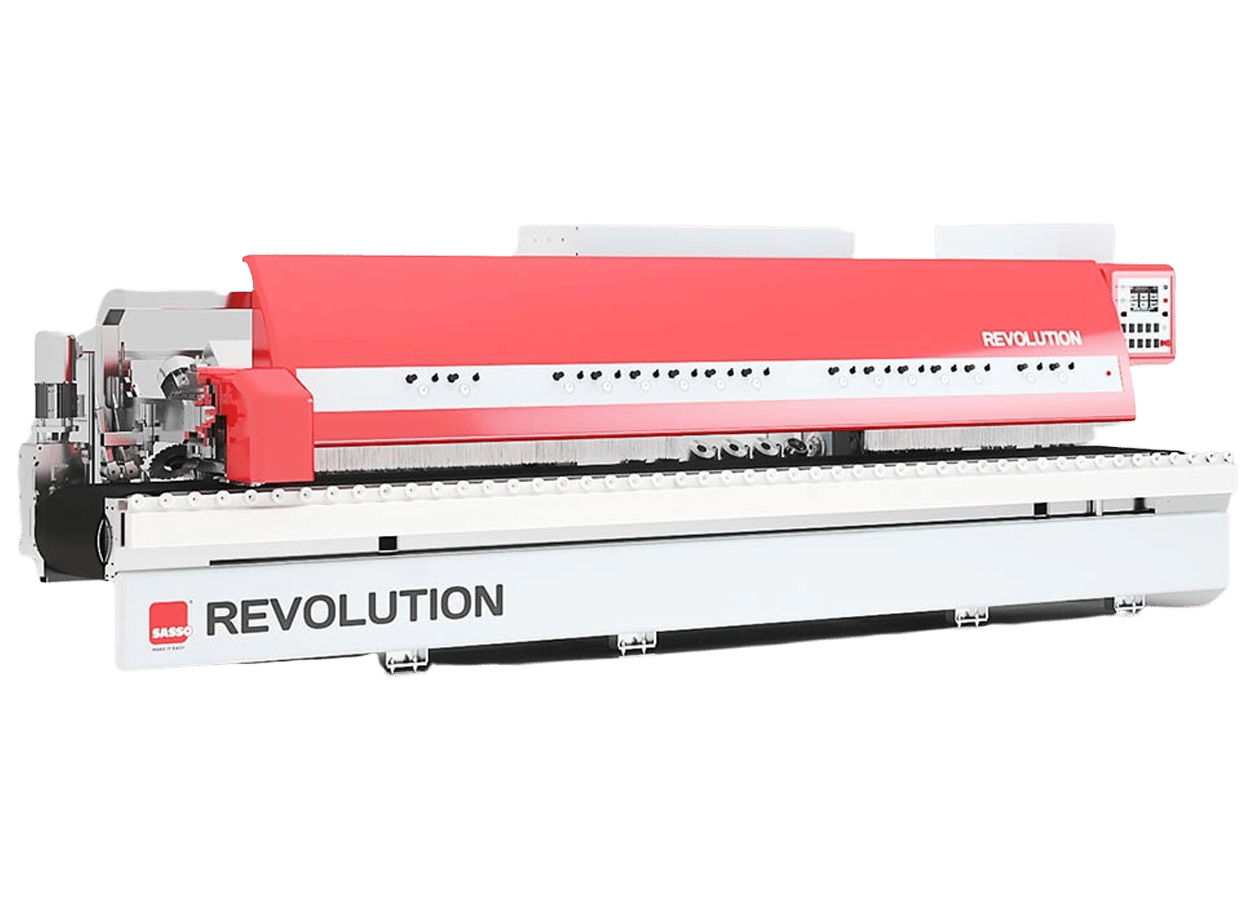

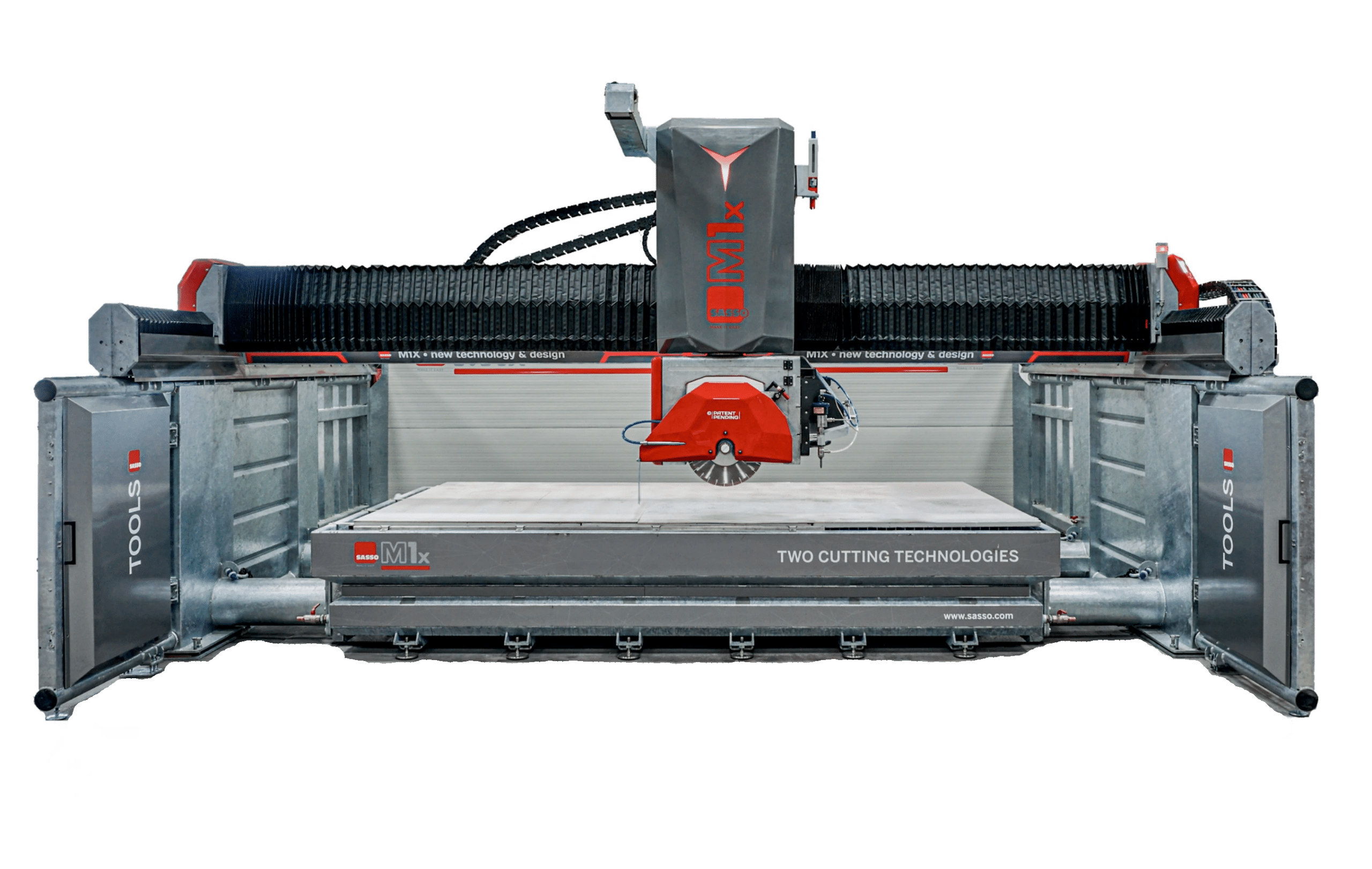

This is no ordinary Five Axis Saw - it's a beast that's loaded with value and power, ready to take your business to the next level. It's your trusted worker, an easy-to-maintain solution that won't quit on you. With the M1, you're set for cutting success, now and for years to come! Call today to get more information and a detailed proposal with pricing and options.

$3808 Per Month Lease

$0 Down

84 Months

Equivalent to a $23.80/HR Employee Pay Rate

M1x

BY

Features

Automatic Lubrication

Wireless Remote Pendant

Advanced PC Controller w/Touchscreen

Collision Avoidance

Slab Thickness Probe

Tool Measuring System

About The M1x

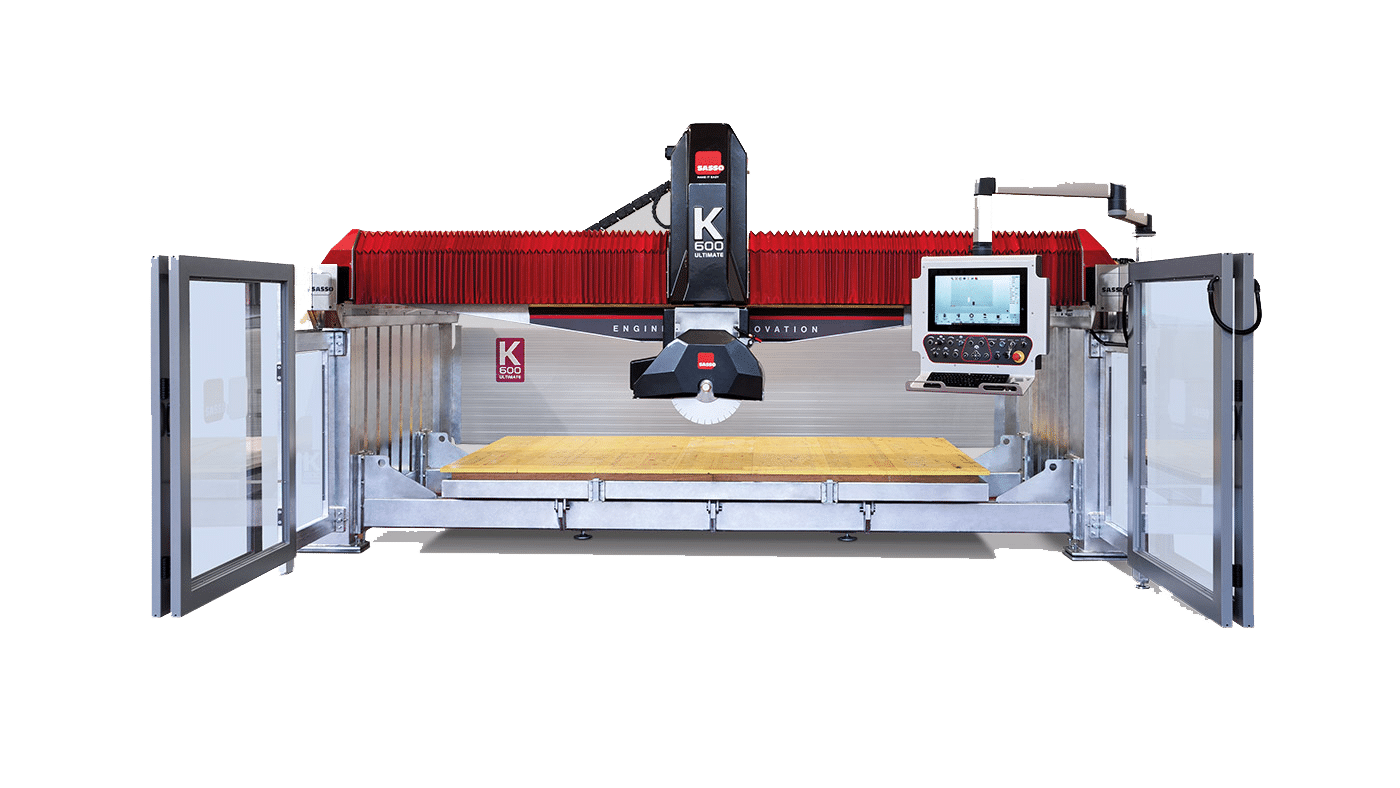

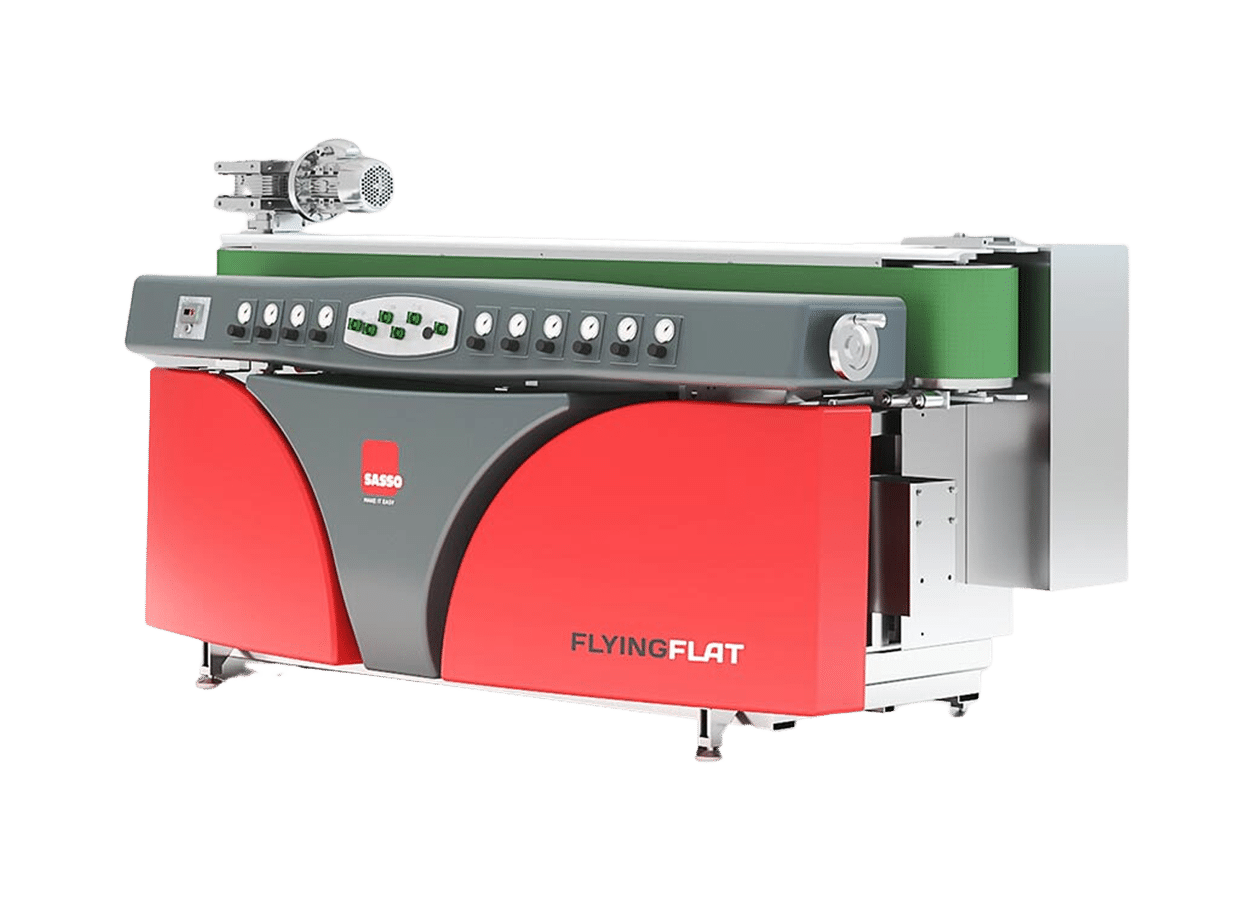

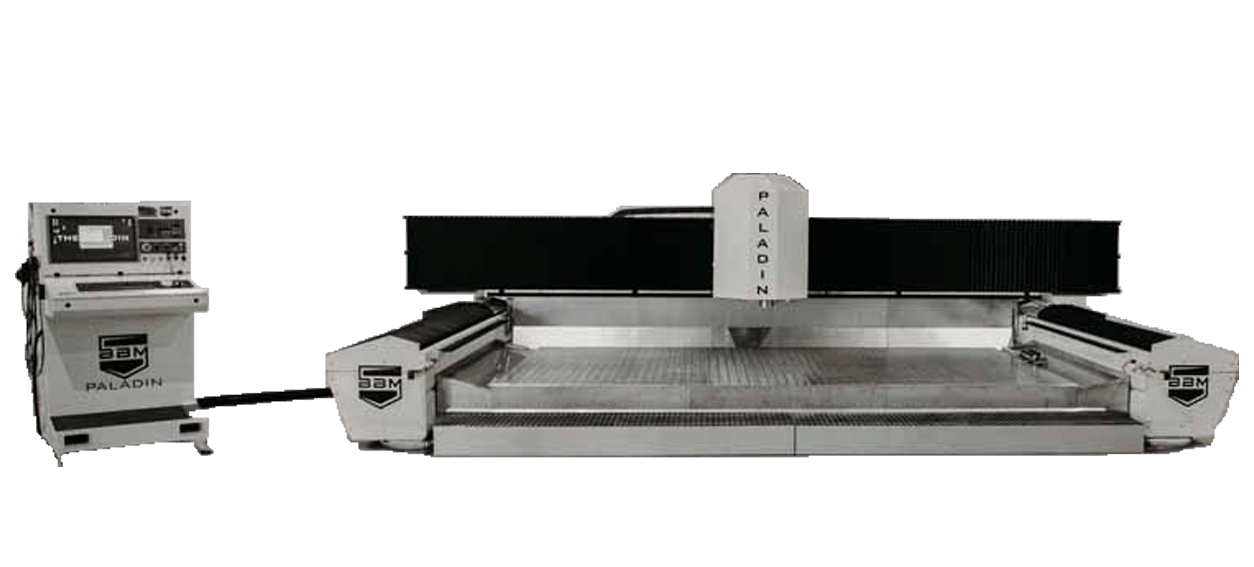

RIGID MONO BLOCK UNIFIED STRUCTURE

The M1 stands out with its monoblock design. It uses round tubing for enhanced rigidity, which is firmly embedded and welded into the sidewalls. We've also built the electrical panel right into the machine frame, which further strengthens its structure. This isn't just about aesthetics; it's about making the M1 as robust as possible. When you choose the M1, you're choosing a tool that's designed to be stronger, built to last, and ready to deliver superior performance. This is more than just a saw - it's a testament to thoughtful engineering.

BRIDGE DESIGN

The M1's bridge design is unique. It's engineered to be stronger, yet lighter. By ditching the drive shaft for a dual servo setup, the bridge is more rigid and moves faster. This change doubles the drive power while reducing weight. That's not just good design, it's strategic engineering. With the M1, you get strength, speed, and efficiency in one package. Engineering really does matter if you want the saw to move faster while maintaining rigidity.

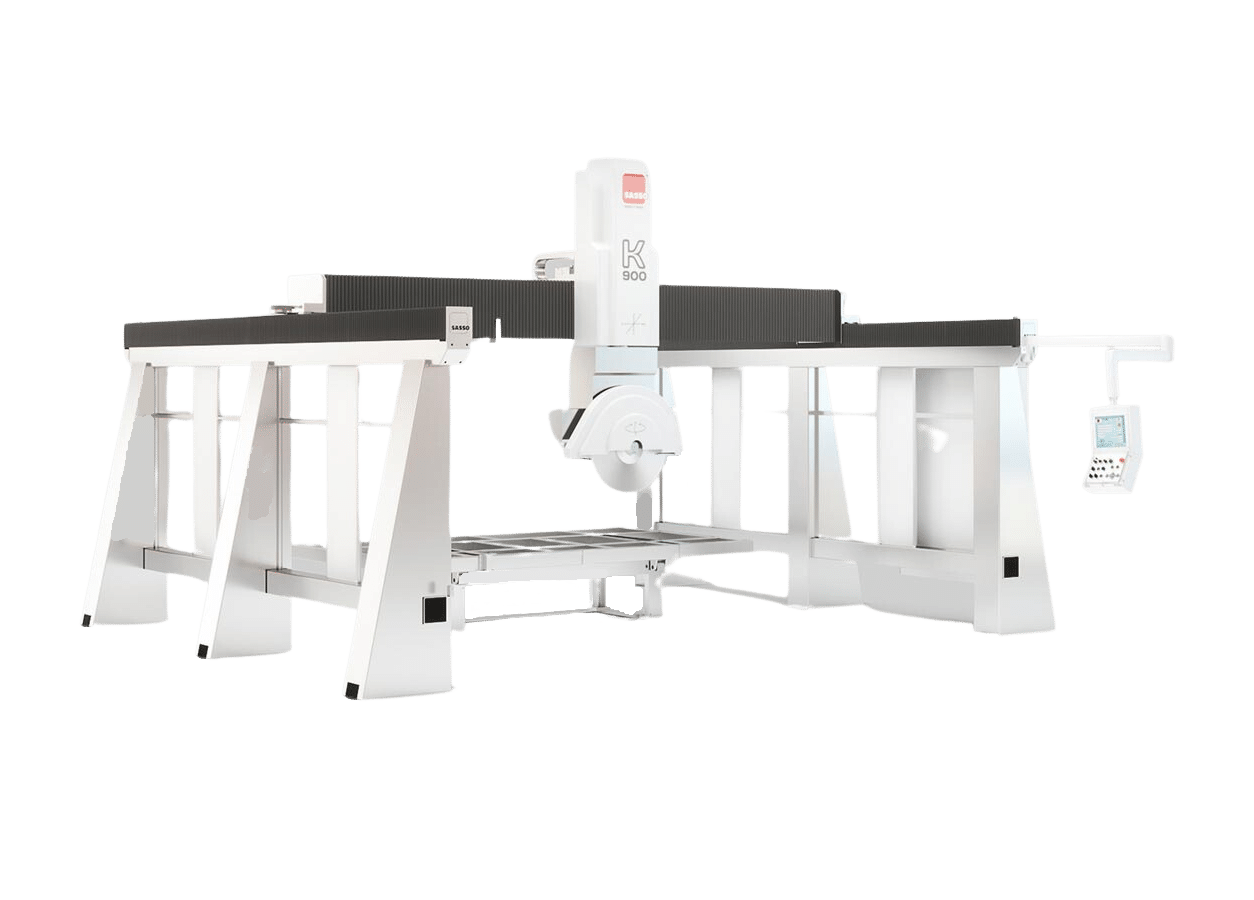

COUNTER BALANCE SYSTEM

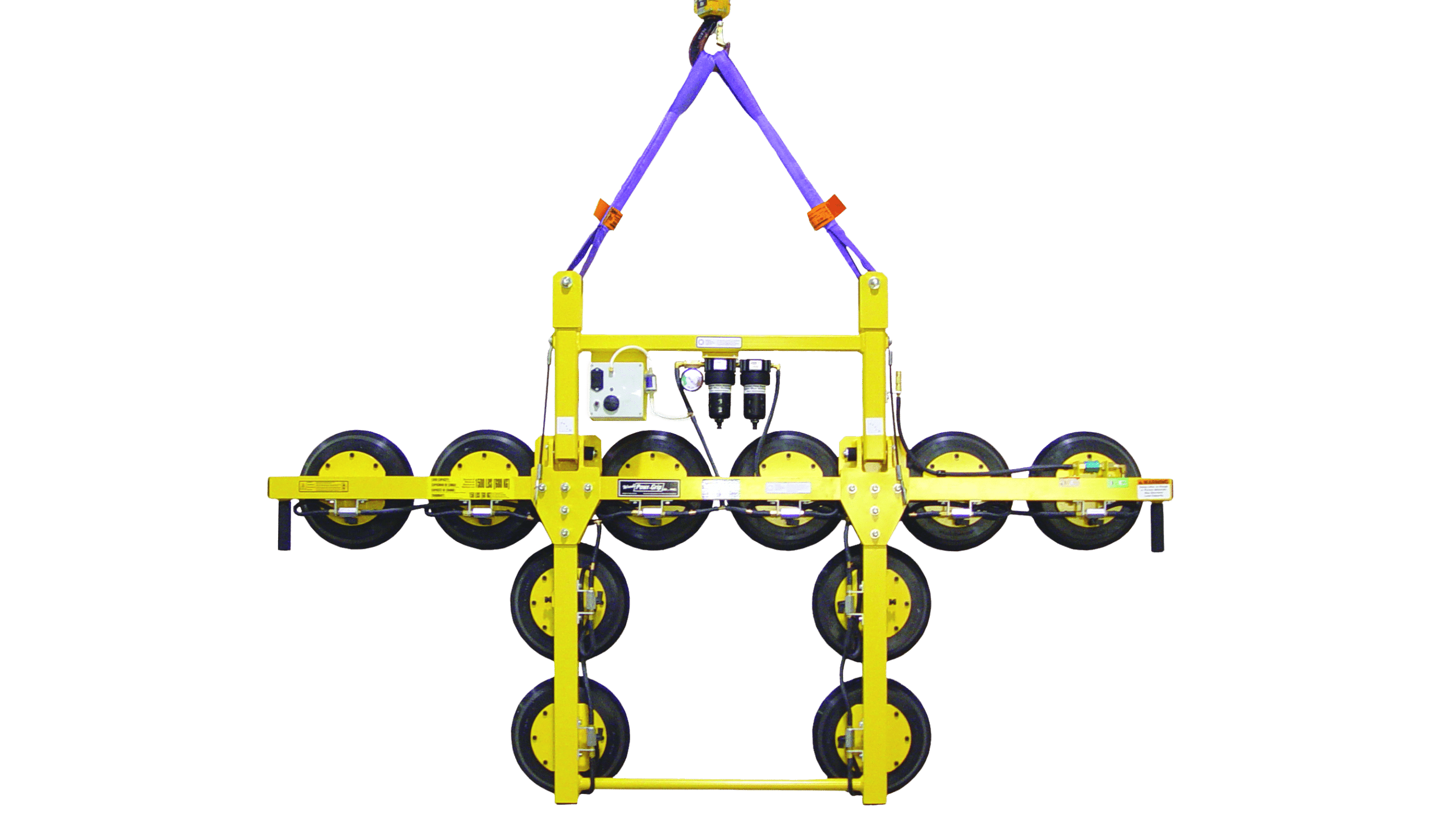

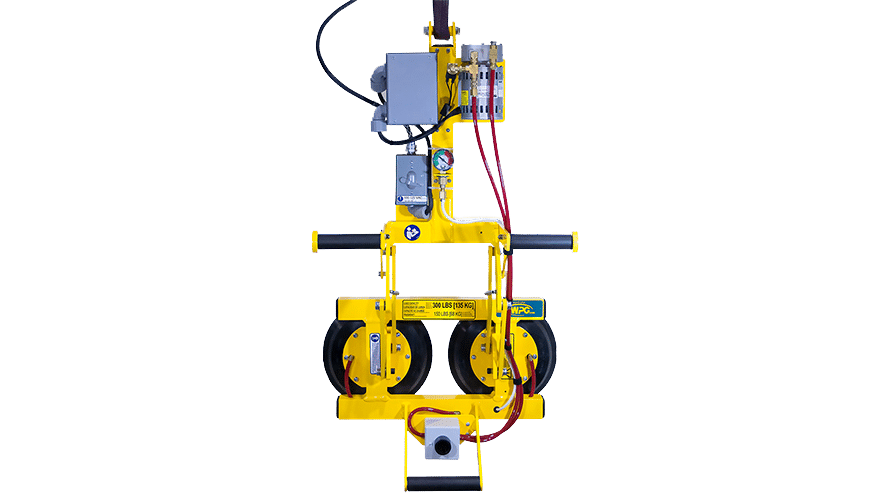

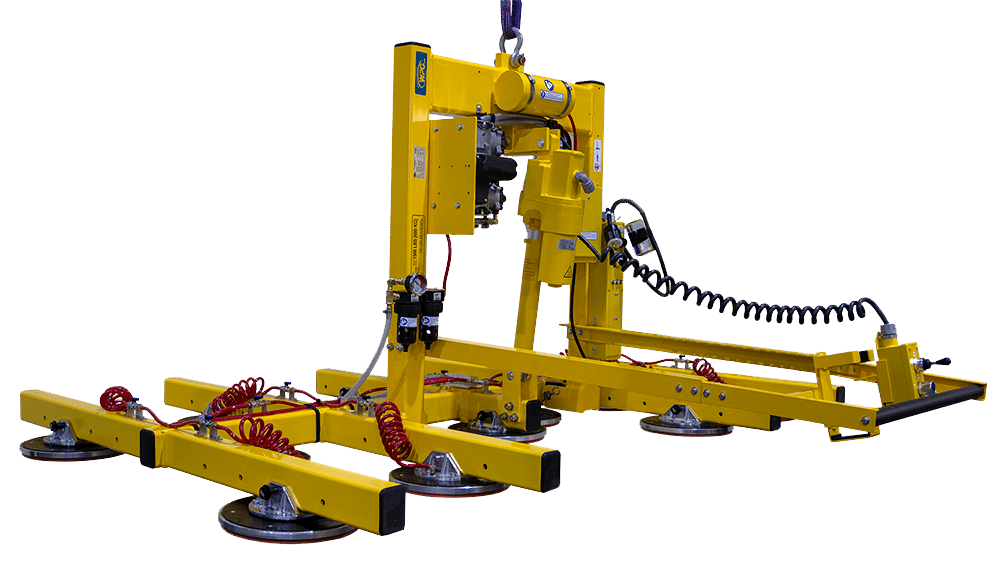

The M1 brings something special to the table - a pneumatic counterbalance system. Air cylinders bear the weight of the tool plate and the saw motor, leaving the servo free to do what it does best - position swiftly and accurately. Using the vac lifter module? The counterbalance system steps up to carry the weight of the slab too. The result: less strain on the ball screw and servo. In the world of stone fabrication, longevity and precision matter. The M1 delivers on both fronts by running smoother and lasting longer.

ADDITIONAL CROSS-PLATFORM FEATURES

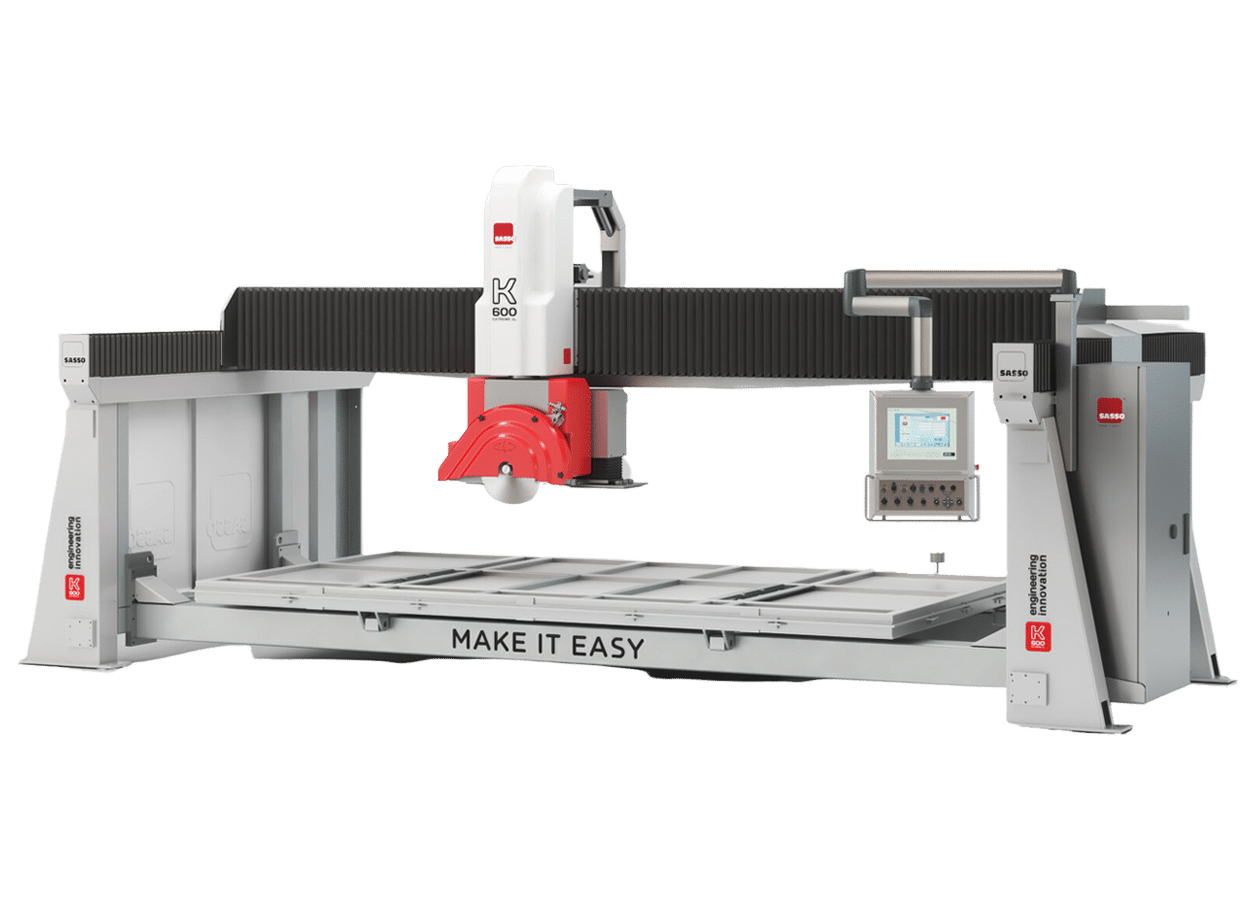

ALPHACAM CAD/CAM WITH COLLISION AVOIDANCE

The M1 stands out with its monoblock design. It uses All Sasso CNC Saws come with state of the art CAD/CAM software. The software is designed to make cutting and milling a simple, fast and productive for your machine operator.

ADVANCED PC CONTROLLER WITH TOUCHSCREEN

Our large touch screen PC controls allow for orthogonal cutting, semi-automatic cutting and parametric cutting from the controls. It allows you to preview the project BEFORE you start cutting. You can access job files, the internet, remote tech support and any other tasks you can do on a computer.

AUTOMATIC LUBRICATION

All of the motion control rails and bearings on the M1 platform have the option for an automated lubrication system that makes maintaining your system easier than ever.

GALVANIZED FRAME PREVENTS CORROSION

Paint chips, peels and rusts over time. All Sasso machinery is hot galvanized to prevent rust and protect your investment.

WIRELESS REMOTE PENDANT

The wireless pendant is used to manually position the head for manual cutting and maintenance.

SLAB THICKNESS PROBE

A precise probe is mounted to the saw head to measure the thickness of the slab. (Very useful if you do a lot of mitering)

TOOL MEASURING SYSTEM

Sasso has built a device that allows you to automatically measure blade diameter AND tool length (lasers don’t do a great job).

FABRICATOR FRIENDLY FEATURES

Integrated tool cabinets, hose bib inside saw for cleaning slabs, under bridge lighting, lovely doors and much more.