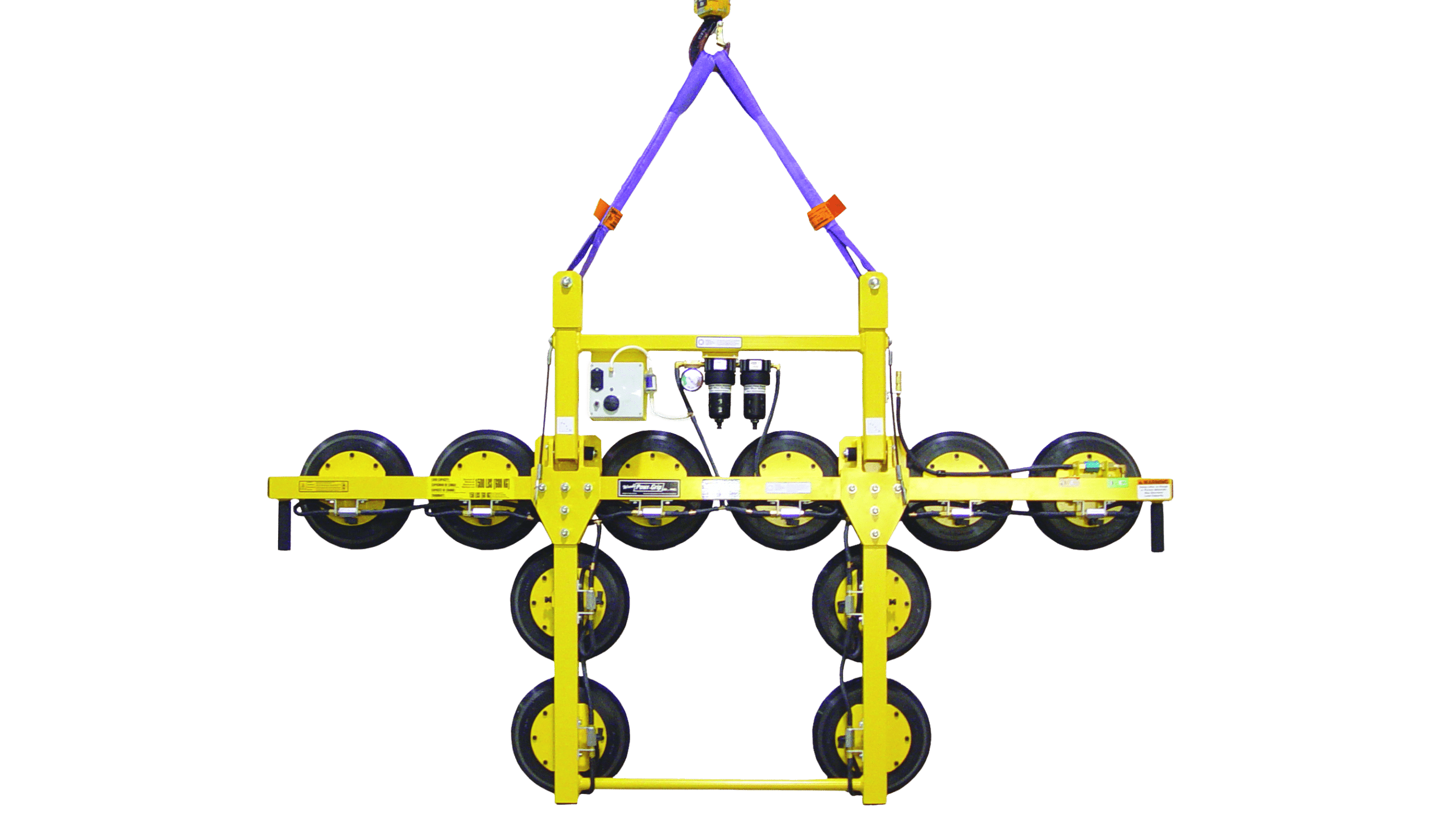

A ceiling mounted version of our work station bridge crane is manufactured from aluminum or steel, offers a similar coverage profile, and perfect when you need to keep the production floor clear of obstructions. Here are some key features of our Ceiling Mounted Work Station Cranes:

- Built to order. A production manager can easily adjust the crane design and location to work with their ever changing facility and work flow. Whether it be adjusting the runway length or adding additional bridges, your Gorbel® workstation crane can help ensure production efficiency where you need it most.

- Flexible design. With this system, the production manager can easily add or subtract extra sections to the track along the runway to fit the mechanical task or the transport of heavy loads. The bridge span can be up to 34 feet long.

- Safe hoist operations. Each track profile is has a built in impact safety factor and is predesigned to accommodate hoist weight. A trolley operator can ensure the safe and ergonomic movements (vertical and/or horizontal) of the load or parts assembly at any point along the track.

- Dependable and precise. Any production or distribution facility that has workers manipulating heavy loads faces greater risks of accidents. Because the entire mechanism will stay rigid (allowing for zero movement of the load), workers can carry out assembly or hoisting tasks with confidence.